PROJECT & PARTNERS

Using the experience and expertise gained with the development of selected application cases, WoodC.A.R. will conclude its work with an ample ecologic and economic assessment of wood as loadbearing material in dynamically loaded structures. Wood in automotive engineering will be one of the possible applications, but WoodC.A.R. tries to open new applications for wood by means of material simulation and computer aided engineering.

Beside technological aspects, quality assessment and economic (bio-economy concepts, life-cycle analysis) will be considered.

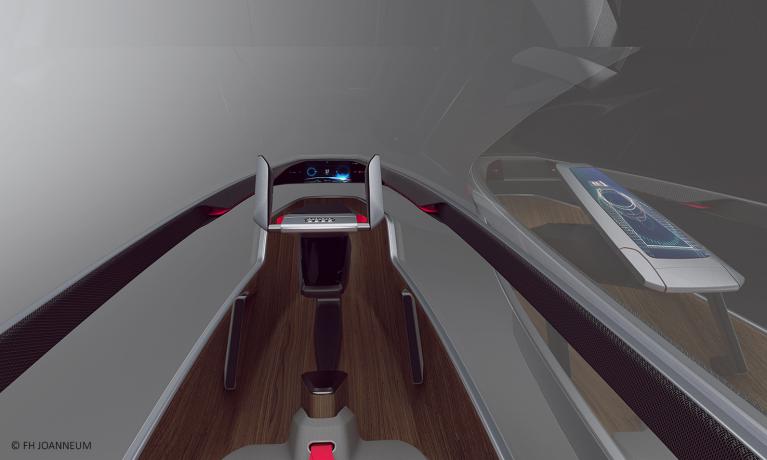

(Click to enlarge image)

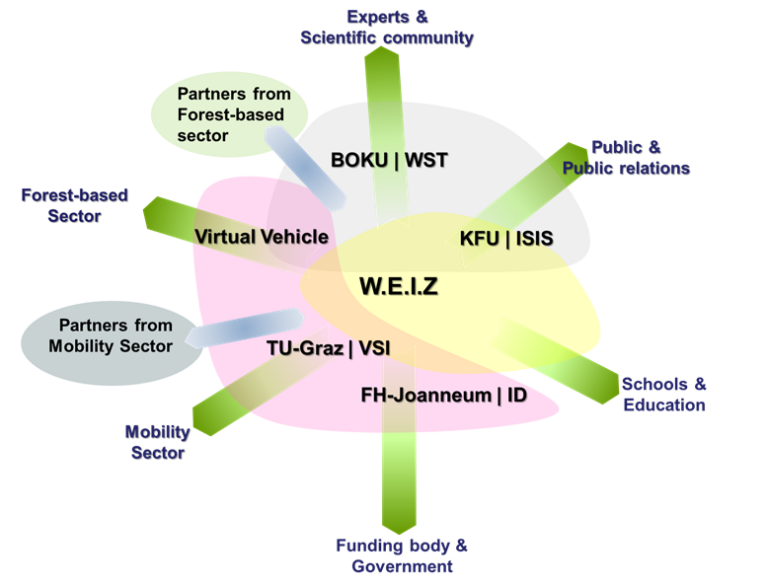

Research design: FH JOANNEUM in cooperation with Weizer Energie- Innovations- Zentrum GmbH, Universität für Bodenkultur Wien, VIRTUAL VEHICLE Research Center, Technische Universität Graz and MAN Truck & Bus AG.

Training Programme and Building of a New Network

The actual work between the wood and automotive industry and the scientific partners started in 2014 by performing a training programme in the framework of FFG “Qualifizierungsnetzwerk” imitated by HC-Styria and AC-Styria. The training programme included expert lectures from the automotive and wood sectors as well as innovation workshops on finding possible application cases for the implementation of wood in the automotive industry. Beside the potential of wood and wood-based materials for the automotive industry also the demand of computer aided engineering and material simulation for the wood branch was pointed out.

Differences of the Wood- and Automotive Branches and Potential of Improvement

Different approaches to development, innovation and production was also the starting point of a subsequently performed innovation project in the framework of FFG “Innovationscheck Plus”. In cooperation with the participating company partner Lean Management Consulting GmbH (Lean MC), the current state of quality management and supplier relationship of the wood industry in Austria and differences between the wood and automotive branch were assessed by means of expert interviews and an online survey. Based on this study a high potential for improvement of the supplier relationship as well as for the whole product development process for the wood industry was assumed. Additionally, the study showed the deficiencies of the wood branch with respect to quality management, documentation as well as special tools such as Failure Mode and Effects Analysis (FMEA) applied in supply chain of the automotive industry. Lean MC will have a special focus, inside and outside the WoodC.A.R. project to guarantee qualification of wood companies which will be acting as Tiers within the automotive supply chain in the future.

Feasibility Study – Proof of Crash Simulation for Wood Materials

Further discussion of the core team of the consortium pointed out that a proof of feasibility with respect to material simulation, forming and special production processes and economical aspects is lacking. Wood and wood industry will find no access to the mobility sector without finding answers to these core topics and without proving that it is possible to simulate wood in a crash situation. Based on this conclusion it was decided by the consortium to perform an extended feasibility study. Within 12 months a research programme was developed and executed with a total budget of more than 650.000 EUR. 100.000 EUR of the total budget was funded by FFG K2 project D1T9sp in the framework of the COMET K2 Mobility programme of the Virtual Vehicle Research Center (ViF). The research programme of the feasibility study included the selection and adaption of a material model, generation of material data by literature research and material testing, selection and engineering of components, component crash tests and validation of the crash simulation as well as the estimation of the economic and technological potential of wood in automotive applications.

Simulation of wood and EWCs under static condition and in crash situation was defined as a central question within this feasibility study, with the following results:

Scientific Partners

Business Partners

The K-Project WoodC.A.R. – Computer Aided Research is funded within the scope of COMET - Competence Centers for Excellent Technologies by BMK, BMDW and the federal states Styria and Tyrol. The program COMET is managed by the FFG.